Application Note: Surface Prep for Wire Bonding

Surface Preparation for Wire Bonding

Cleaning Solution for Bond Pad Contamination

Introduction

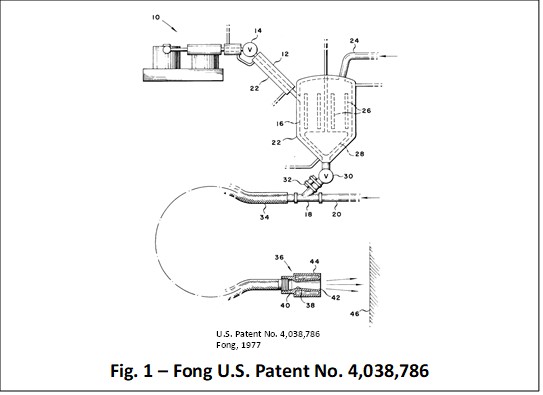

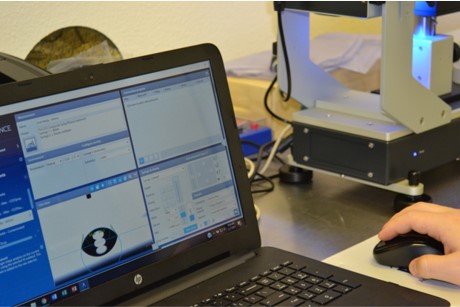

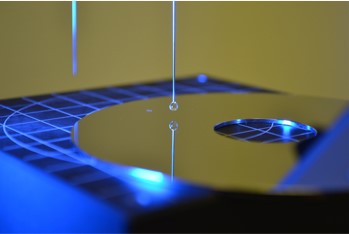

Shown in Figure 1 is a typical wire bonding procedure. To ensure bondability and reliability of wire bonds, one of the critical conditions is that the bonding pad surface must be free of contaminants (1).

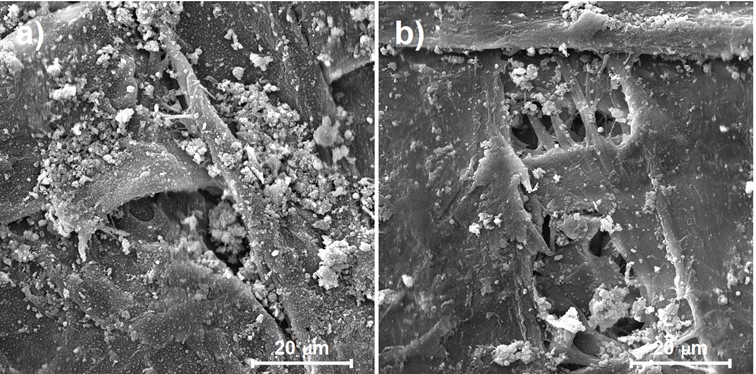

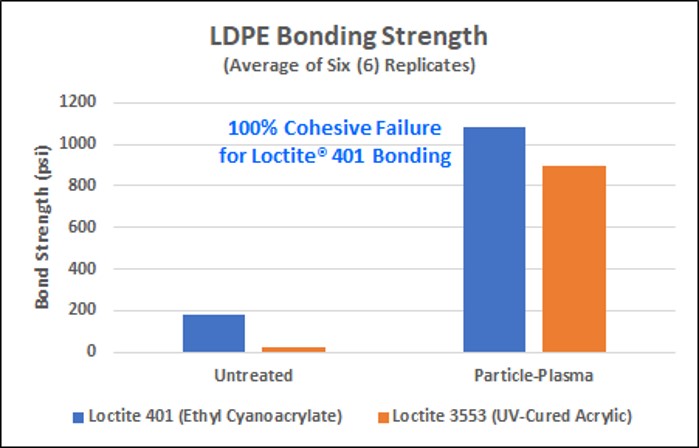

Therefore, bond pad cleaning is an important step prior to wire bonding. Selective CO2 spray cleaning technology offers a robust and flexible technique for achieving cleanliness on bond pads. A bond pad can be made very clean and wettable by removing residues, particles and activating the surface.