Cleaning Delicate Surfaces Using Sub-Micron Sized Solid Carbon Dioxide Particles Propelled by Gaseous Carbon Dioxide

Cleaning Surfaces with Dry Ice

Cleaning delicate surfaces using sub-micron sized solid carbon dioxide particles propelled by gaseous carbon dioxide (i.e., “Snow” or “CO2 Aerosol Spray”) was first proposed by Dr. Stuart Hoenig (University of Arizona), in Hoenig, S.A., “Cleaning Surfaces with Dry Ice”, Compressed Air Magazine, August 1986, pp. 22-25 (Hoenig 1986). Hoenig 1986 describes depressurizing (expanding) liquid carbon dioxide through a long and large diameter cylindrical tube of uniform diameter. The expansion effect produced a low-velocity and large flaky snow mass. Hoenig 1986 further taught a concentrically positioned tube over the expansion tube which added a flow of dry nitrogen shrouding gas to prevent build-up of condensation on substrates during the application of the CO2 aerosol. This was the first recorded use of a CO2 snow spray to clean a surface with an artificial atmosphere to mitigate condensation from the surrounding atmosphere.

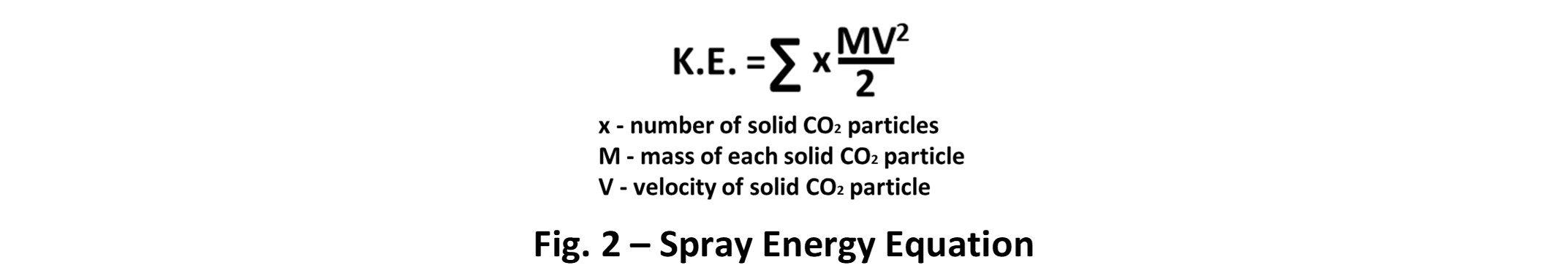

Carbon dioxide aerosol spray cleaning phenomenon (physical cleaning effects) is understood using the kinetic energy equation. The energy available in any spray stream can best be described by the sum of the kinetic energy of each solid CO2 particle in the stream as defined in the equation shown in Figure 2.

For gaseous sprays (i.e., clean compressed dry air) the kinetic energy available is limited by the mass of the gas molecules, thus the energy of a gaseous spray stream can only be increased by increasing the velocity of the gas molecules. Typically, gaseous spray streams do not have enough energy to remove contaminants from a surface that are strongly adhered and chemical in nature, such as fingerprints. They are best suited for blowing off loose dirt particles and dust. Increasing the spray stream's energy one or two orders of magnitude by increasing the line pressure still does not add enough energy to enable a purely gaseous spray stream to remove stubborn contaminants.

Compared to a gas blowoff cleaning technique, the carbon dioxide aerosol spray (aka CO2 Snow Spray) contains significantly more mass with the introduction of the solid carbon dioxide particles. This increases the kinetic energy available in the stream acting on a surface. The CO2 aerosol spray, even with a nozzle exit velocity much lower than a gaseous spray stream, will remove very small particulate contaminants. In fact, the CO2 aerosol spray will remove submicron particles that the gaseous spray stream is unable to remove at any nozzle exit velocity.