David Jackson

David Jackson, aka The CO2 Guy, is Founder and President of CleanLogix LLC and Clean Imagineering LLC, based in Santa Clarita, California. David’s companies work in partnership to manufacture and distribute synergistic clean manufacturing products and services for precision cleaning, hard machining, thermal control, value extraction, precision drying, sample testing, process fluids supply and management, and smart manufacturing. David also serves as Clean Manufacturing Consultant to Hitachi High-Tech, Japan, to develop and deploy Hitachi-brand CO2 enabled precision cleaning and metalworking fluid products (clean solutions) for high-volume and high-reliability product manufacturing. David began his career as group head of precision cleaning and contamination control at Hughes Aircraft Company in the 1980’s. There he developed the first CO2-based precision cleaning techniques as chlorofluorocarbon (CFC) solvent replacement processes for use in the production of advanced aerospace communications and warfare devices. David holds a Bachelor’s Degree in Chemistry, has authored or co-authored numerous technical articles and presentations, and has been issued more than 40 patents worldwide. David has developed and commercialized more than twenty clean manufacturing products utilizing environmentally-safe and renewable chemistries including CO2, hydrogen peroxide, ozone, bio-based hydrocarbons, and atmospheric plasma. Over the past 35 years, David’s unique expertise and innovations have provided numerous Fortune 100 and 500 manufacturing companies worldwide with cost- and performance-effective tools to improve product quality, increase productivity, reduce manufacturing waste, lower cost of production, and improve the environmental quality in their factories. • Renewable Chemistries for Precision Cleaning, Machining Processes, and Value Extractions • Centrifugal, Microwave, and Ultrasonic-Assisted Cleaning and Extraction Processes • Cleaning, Cooling, and Lubrication Processes using Solid, Liquid, Plasma, and Supercritical CO2 • Non-contact Surface Analysis Methods • Atmospheric Plasma Surface Treatment Methods • Manufacturing Waste Minimization Assessments • Cleaning Process Development and Cleanliness Validation • 3D Product Design and Fabrication • PLC/iPC Control Panel and Software Development • Robotic Process Automation • Contract Cleaning Services • Smart Manufacturing Consulting

Applications

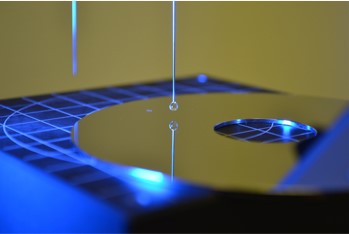

Surface Preparation for Wire Bonding

Cleaning Solution for Bond Pad Contamination

Introduction

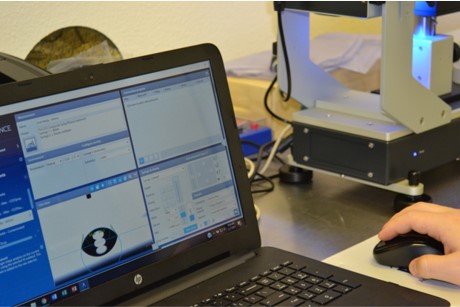

Shown in Figure 1 is a typical wire bonding procedure. To ensure bondability and reliability of wire bonds, one of the critical conditions is that the bonding pad surface must be free of contaminants (1).

Therefore, bond pad cleaning is an important step prior to wire bonding. Selective CO2 spray cleaning technology offers a robust and flexible technique for achieving cleanliness on bond pads. A bond pad can be made very clean and wettable by removing residues, particles and activating the surface.

David Jackson

Jul 10, 2024 9:35:44 PM

History of CO2 Composite Spray

Cleaning Delicate Surfaces Using Sub-Micron Sized Solid Carbon Dioxide Particles Propelled by Gaseous Carbon Dioxide

Cleaning Surfaces with Dry Ice

Cleaning delicate surfaces using sub-micron sized solid carbon dioxide particles propelled by gaseous carbon dioxide (i.e., “Snow” or “CO2 Aerosol Spray”) was first proposed by Dr. Stuart Hoenig (University of Arizona), in Hoenig, S.A., “Cleaning Surfaces with Dry Ice”, Compressed Air Magazine, August 1986, pp. 22-25 (Hoenig 1986).

David Jackson

Jul 17, 2023 6:31:18 PM

History of CO2 Composite Spray

The First CO2 Spray Cleaning Process

Fong's (Lockheed Aircraft) Pellet Blast Process

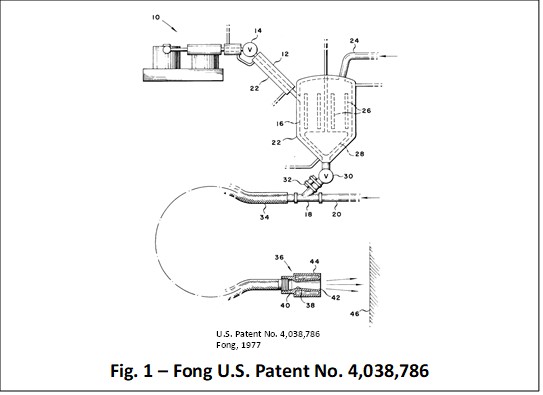

During the 1970’s, Calvin Fong, Lockheed Aircraft Corporation, Burbank California, developed the very first surface cleaning process utilizing “sublimable particles” – solid carbon dioxide pellets – entrained in a compressed air stream. Shown in Fig. 1, the Fong invention is described in detail in U.S. Patent No. 4,038,786, “Sandblasting with pellets of material capable of sublimation”, August 1977 (Fong 1977).

David Jackson

Jun 26, 2023 8:59:48 AM

History of CO2 Composite Spray

The Short Story

CO2 Composite Spray Technology Development

CO2 Composite Spray™ technology can claim its beginnings going back to the late 1970’s with the introduction of Fong’s pellet blasting innovations when he was working for Lockheed Aircraft. CO2 pellet blasting employs a mixture of small (sublimable) solid CO2 pellets (used almost exclusively for food packing refrigeration) introduced into a compressed air stream to blast contaminated surfaces free of gross contamination.

David Jackson

Apr 4, 2023 7:15:54 PM

CO2 Processing Technology

Bondability

CO2 Technology Improves Bondability

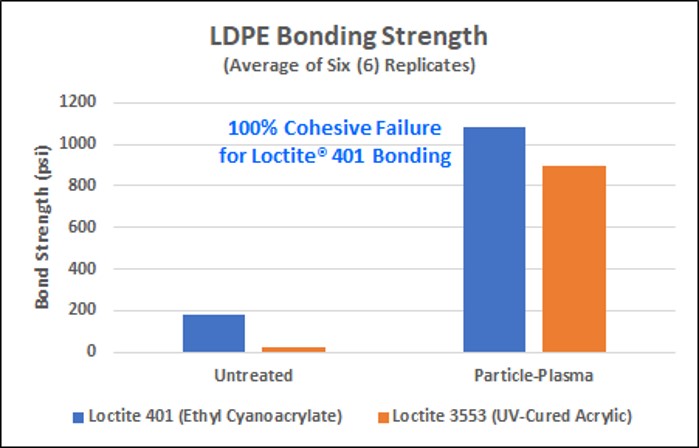

A manufactured product may require component surfaces to be joined using methods such as gluing, welding, soldering, and coating. The ability of a surface to be cohesively or adhesively joined or bonded to another surface is termed bondability.

David Jackson

Aug 4, 2021 12:22:30 PM

CO2 in the News

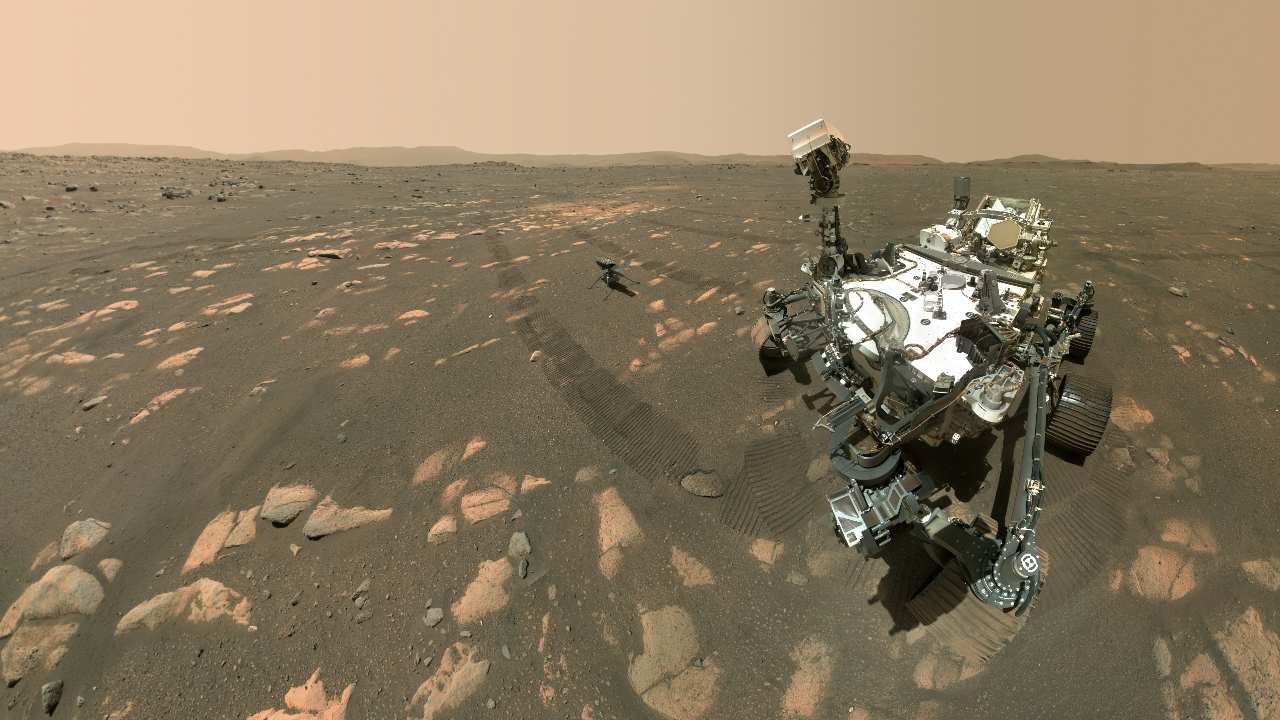

Perseverance rover converts CO2 into oxygen on Mars for the first time

MOXIE produced five grams of oxygen, equal to 10 minutes of breathable oxygen for astronaut carrying out normal activity

David Jackson

May 26, 2021 2:15:32 PM

CO2 Processing Technology

Wettability

CO2 Improves Surface Wettability

A manufactured product may require component surfaces to provide fast and uniform spreading and contact of applied (liquids) adhesives, coatings, paints, sealants, underfills, or molten metals. The ability of surface to be wetted by another substance is termed wettability.

David Jackson

Mar 8, 2021 3:41:39 PM

CO2 Application Profiles

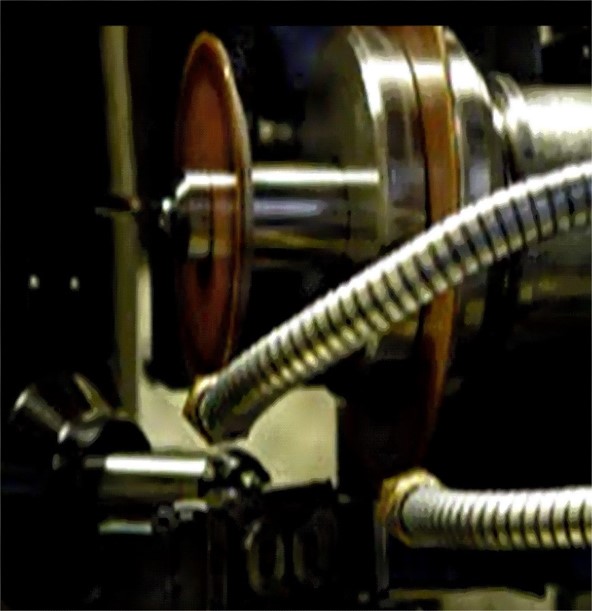

CO2 MQCL for Titanium Machining

Atmosphere. Optimized.

Introduction

The past century has witnessed significant advancements in cutting machines, cutting tools, machine controls, processing materials, and cooling-lubrication chemistries. However, surprisingly very little has changed with regards to the application of coolants and lubricants during machining – the machining atmosphere.

David Jackson

Feb 8, 2021 3:46:51 PM

CO2 Processing Technology

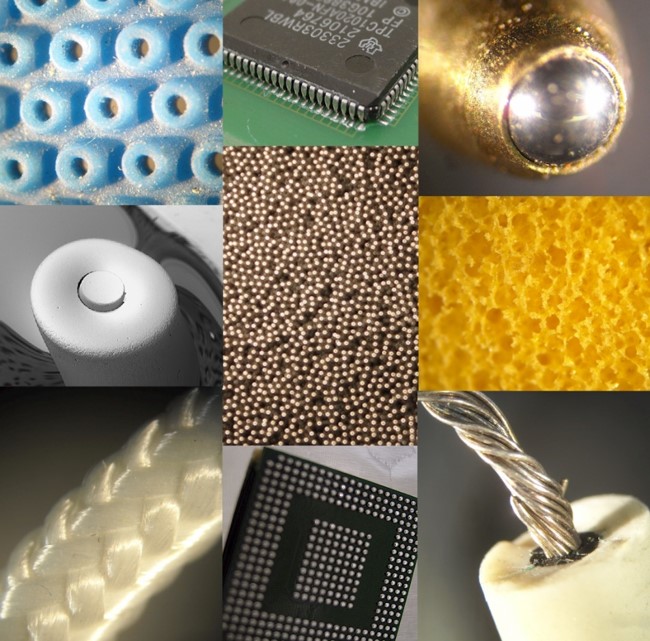

Cleanability

CO2 Improves Surface Cleanliness in Different Ways

A manufactured product may require components to have a certain maximum level of surface contaminants such as particles and oils to enable wetting, bonding, or machining operations, or to enable assembly, testing, or functional performance of the product. The ability of surface to be cleaned to a pre-determined and desired cleanliness level, efficiently and without damage to the surface or product, is termed cleanability.

David Jackson

Jan 25, 2021 7:13:22 PM

CO2 Processing Technology

Surface Transformations

CO2 Changes Surfaces in Different Ways

The most practical and unique aspect of CO2 processing technology is its ability to transform the chemical and physical nature of a manufactured surface, selectively or non-selectively, and in many different ways. Example surface transformations include dirty-to-clean, hot-to-cool, low surface free energy-to-high surface free energy, high outgassing-to-low outgassing, and non-polar-to-polar.

David Jackson

Jan 11, 2021 10:12:42 PM