Surface Transformations

CO2 Changes Surfaces in Different Ways

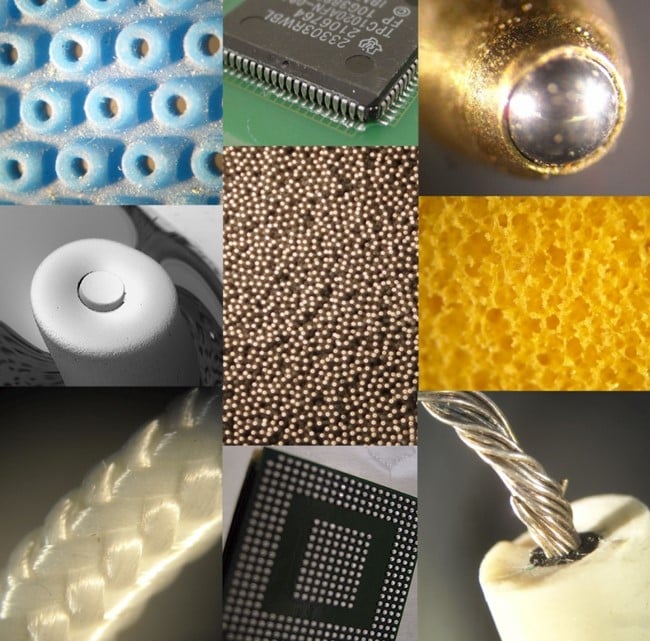

The most practical and unique aspect of CO2 processing technology is its ability to transform the chemical and physical nature of a manufactured surface, selectively or non-selectively, and in many different ways. Example surface transformations include dirty-to-clean, hot-to-cool, low surface free energy-to-high surface free energy, high outgassing-to-low outgassing, and non-polar-to-polar. CO2 -enabled surface changes may be classified or categorized according to the following exemplary surface transformations:

Cleanability: The ability of a surface to be cleaned; for example, to remove inorganic particles, oily films, loose oxides, ionic residues, bioburden, and outgassing compounds;

Wettability: The ability of a surface to be wetted by another substance; for example, by coatings, adhesives, paints, sealants, and molten metals;

Bondability: The ability of a surface to be bonded or joined to a mating substrate; for example, adhesives, sealants, adherents, or weldments;

Machinability: The ability of a surface to be machined; for example, by cutting, forming, or grinding tools and processes; and

Coolability: The ability of a surface to be cooled to an optimal temperature; for example, during turning, precision abrasive grinding, or thermal spray coating processes.

In many manufacturing processes, a combination of (optimized) surface transformations are required for peak performance. Examples include:

Precision Cleaning: Cleanability, Wettability

Adhesive Bonding: Cleanability, Wettability, and Bondability

Abrasive Grinding: Cleanability, Wettability, Machinability, and Coolability