CO2 Backstory 1.3

CO2 Technology Development

Faster, Better and Cheaper

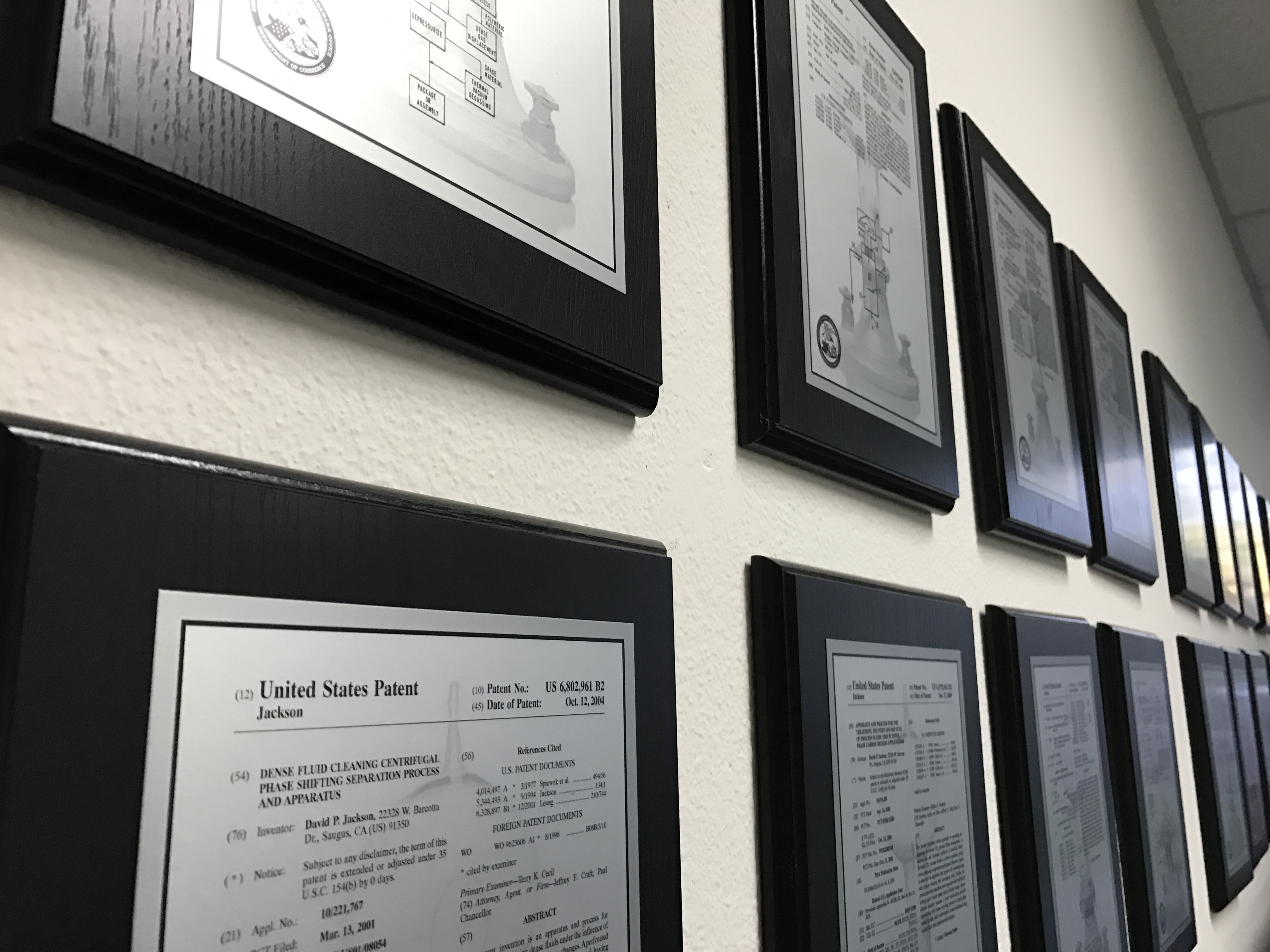

CO2 technology described in this blog-eBook represents more than 30 years of process, application, and commercial product development beginning in 1984 and continuing to the present day. The old adage – Necessity is the Mother of Invention – has been and continues to be a major driving force behind the CO2 technology innovation process. Discrete cleaning, surface modification, cooling, purification, and recycling technologies represent derivatives – various CO2-enabled solutions ideated, developed, and advanced to jointly solve production cleaning and contamination control problems encountered in numerous end-user manufacturing applications to achieve specific performance requirements. In this regard, rapid changes in manufacturing technology, shrinking product features, and increasing global competitiveness have driven the need for sustainable manufacturing technology - faster processing, better performance, and a lower cost of production.